Product Introduction

- Home

- Products

- PETG / PCTG / PET / TPEE / PO3G

- Skygreen

PETG / PCTG / PET / TPEE / PO3G

Skygreen

PETG,PCTG- Features

- BPA Free

- High transparency with 90% light transmittance

- Chemical resistance

- Impact resistance

- Stress whitening resistance

- Commonly used as a substitute for PC, PMMA, and PVC

Description

PETG and PCTG

High-performance copolyester product with excellent transparency, chemical resistance and superior process ability.

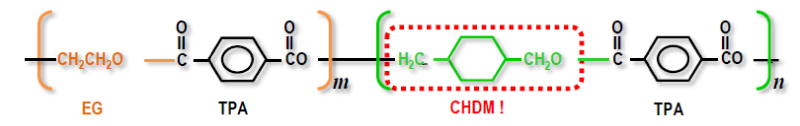

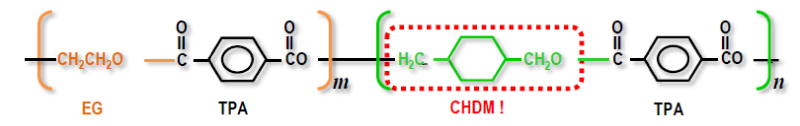

PETG / PCTG

PETG/PCTG amorphous copolyester = EG (terephthalic acid) + TPA (ethylene glycol) + CHDM (1,4-cyclohexanedimethanol)

Specification Table

| Skygreen | PETG | PCTG | ||

|---|---|---|---|---|

| Specification | S series | K series | PN series | J series |

| Features | Natural color | High transparency | High flowability | Chemical and impact resistant |

| Extrution | S2008 | K2012 | ||

| Injection and blow | ||||

| High flowability | PN200 | JN200 | ||

Physical Properties

| Test items | Test Methods | Unit | S2008 | K2012 | PN200 | JN200 |

|---|---|---|---|---|---|---|

| Specific Gravity | ASTM D792 | - | 1.27 | 1.27 | 1.27 | 1.23 |

| Mold Shrinkage | ASTM D955 | % | 0.3 ~ 0.6 | 0.2 ~ 0.5 | 0.2 ~ 0.5 | 0.2 ~ 0.5 |

| Rockwell Hardness | ASTM D785 | R-scale | 110 | 108 | 105 | 105 |

| Tensile Strength Yield | ASTM D638 | Kgf/cm2 | 455 | 455 | 470 | 460 |

| Tensile Strength Break | ASTM D638 | Kgf/cm2 | 410 | 300 | 470 | 5540 |

| Elongation Yield | ASTM D638 | % | 5 | 4.5 | 4.5 | 5 |

| Elongation @ Break | ASTM D638 | % | 250 | 250 | 120 | 340 |

| Flexural Strength | ASTM D790 | Kgf/cm2 | 705 | 755 | 720 | 680 |

| Flexural Modulus | ASTM D790 | Kgf/cm2 | 21,500 | 22,000 | 19,300 | 18,300 |

| Izod Impact Strength Notched | ASTM D256 | J/m | 100 | 105 | 105 | 860 |

| Heat Distortion Temperature @ 0.455 MPa / @ 1.820 Mpa |

ASTM D648 | ℃ | 70 / 62 | 70 / 62 | 70 / 62 | 74 / 64 |

| Haze | ASTM D1003 | % | < 1.0 | < 1.0 | < 1.0 | < 1.0 |

| Transmittance | ASTM D1003 | % | 90 | 90 | 90 | 90 |

Application Project

Cosmetic bottles and jars

Sheet and pipe

Medical insurance

3D printing

Safety Certificate

RoHS EU regulations

US FDA food contact

Circular Economy Gold Medal